The Optical Fiber with the Finger in the Leak

Industry 4.0 Blog

This blog is addressing the Industry 4.0 and includes news and information aroud topics as smart manufacturing, artificial intelligence and Industrial Internet of Things (IIoT).

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Email to a Friend

- Printer Friendly Page

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

The Optical Fiber with the Finger in the Leak

Originally published on Industry 4.0 Blog by Eitanel | February 09, 2021 03:53 PM

On December 2nd, 2020, a city engineer in Walnut Creek, California smelled gasoline, in the concrete flood-control basin passing through the quiet town. It wasn’t long before worried pipeline engineers appeared on site, trying to understand what happened and, better, how to stop it.

Up to 42,000 gallons spilled into a waterway that cuts through a neighborhood. The equivalent is 1,000 barrels, where Federal regulators consider a spill of 50 barrels or more a “significant incident.”

Luckily, no one was hurt, and a month later, cleaning is still taking place. The spill started more than a mile away, and after the pipeline operator found out, oak tree roots cracked the 10-inch steel pipe.

Pipeline leaks - sum of all fears

Such a spill is the sum of all fears for a pipeline operator. A leaking pipeline may be hazardous to human lives, has an enormous environmental impact, and the lost product has a commercial value. A 2004 spill on the same line exploded in Walnut Creek, killing five construction workers and injuring four more.

There could be different reasons for a pipeline to lose its integrity. A small rupture, a strain, a weakening, and then the pressure, the environment, and many other factors create a leak. In many cases, it is a 3rd party intrusion – deliberate or not – that tampers with the pipeline. A malicious attack or an illegal tap, stealing product from the pipeline, is common worldwide. In many other cases, digging activities may interfere with the pipeline integrity and cause a leak. Such incidents -leaks of different magnitude do not occur that often in a given line; however, the impacts are significant when it does happen.

Digging experiment for pipeline customer - fiber senses digger from 25 meters

From the head of operations to a field pipeline worker, leak detection solutions are not a thing of comfort but an essential tool for any pipeline operator. The earliest the warning is, the better. There are many techniques and solutions for this problem, with the more popular and established methods are flow balance and negative pressure wave sensors. There are also pigging solutions with leak detection pigs running inside the line to detect leaks through acoustic data evaluation. However, in many cases, these prove to be either complex, suffer from too many false alarms, or in the case of pigs, the passage of these tools inside the pipe is not always easy (especially if there is an illegal siphon tapping).

In the big equation of detection, low false alarm rates, and cost per km, distributed fiber optic acoustic sensing for leak detection can make a big difference.

What is distributed fiber optic acoustic sensing?

Distributed fiber optic sensing is a set of technological solutions that use optical fiber, commonly installed with pipelines and other long stretch utilities, and turn it into a sensitive array of sensors.

In the case of Distributed Acoustic Sensing (DAS), an interrogator unit is connected to the end of the fiber and uses lasers to send light into the fiber. As the light travels along the fiber for 50-100km, a small percentage is reflected back (backscattering). Acoustic waves and other physical phenomena change the microscopic nature of the fiber (think of a stepping on a garden hose feeding a sprinkler). Thus, the backscattered light detected by the interrogator unit can tell a story of what happened distant kilometers down the fiber.

Intense sounds, vibrations, strain, and temperature changes – all these may change the backscattered light, and a sensitive interrogator can capture these changes. Thus, information from the entire fiber propagates back to the interrogator, turning the optical fiber to a 100km of extremely sensitive and array of microphones. Multiple units can be chained together to listen to an entire length of a pipeline.

As optical fiber cables are installed alongside primary pipes for years back, the solution’s simplicity is unmatched. Deployment across hundreds of kilometers is easy as plugging in an optical fiber. No need to traverse the pipe, maintain a multitude of sensors, etc.

Distributed Acoustic Sensing have been used for some years. Several vendors have been offering such systems which were received with mixed emotions. These solutions had issues with false alarms because of wrong detection caused by low sensitivity and high noise levels. Most of them need to traverse the line to calibrate and configure ‘noisier’ part of the pipeline and many can not use the simple telecom grade optical fiber. Prisma Photonics and PrismaFlow™ are changing all this.

PrismaFlow™ pipeline monitoring

PrismaFlow™ is Prisma Photonics’ solution for oil & gas pipeline monitoring. It represents the next generation of fiber optic sensing. Using distributed acoustic sensing, it can detect very small leaks and, on the other hand, sense 3rd party intrusions such as people digging manually or mechanical digging, kilometers ahead.

Unlike similar systems, PrismaFlow™ uses Hyper-Scan™ fiber sensing to scan in real-time every part of the pipe, from afar. It can detect a mechanical digger engine approaching a pipeline 100km away from the interrogator or a person walking above the pipeline.

PrimaFlow™ uses any type of pre-installed fiber, using a single strand in a multi-fiber cable. It does not matter if the cable was buried directly in the ground or some sort of conduit along the pipeline.

Machine learning algorithms classify each event, ignoring ones that do not represent any problem. Cars on a nearby road do not trigger any alerts, or the above mechanical digger will not trigger a warning if it stays on the road and does not dig).

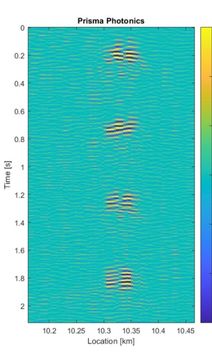

In the following example , PrismaFlow™ shows the footsteps of a person walking 30 meters away from the fiber buried near a pipeline. The classification can rule out animals in case of a horse, a boar, or any other non human. It is the pipeline operations center’s decision whether to trigger an alert for such an event or not.

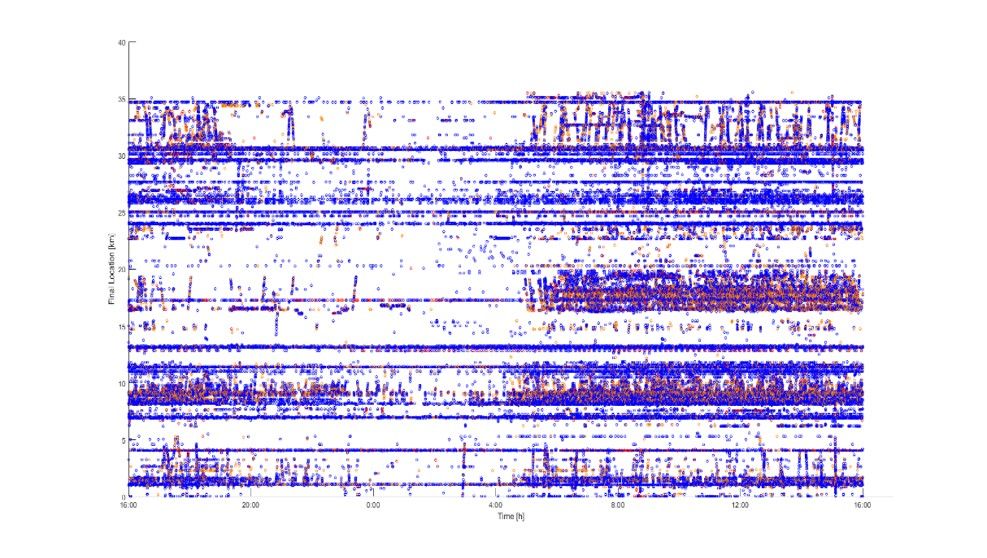

False alarms are the worst enemy of any operations team. With smart classifications, the false alarm rate is kept on a negligible level. In a recent test near a highway, PrismaFlow™ detected 92,514 events due to the constant traffic, none of which was a digging threat,

Aggregation of 92,514 events recorded in 24Hrs - none of them raised a digging alarm

Detecting the smallest leaks

In addition to detecting threats to the pipeline, PrismaFlow™’s high sensitivity can be used to detect and classify very small leaks.

In a proof of concept, an optical fiber was buried 50cm from a pipeline simulating a gas leak. The system detected and classified correctly gas leaks as low as 200 standard liters per minute (SLPM) through a 4mm opening. When testing with liquids to simulate leaks PrismaFlow™ was able to detect and classify a leak as small as 20 liters per minute (LPM).

These rates are very low. Especially taking into account that these can be sensed 10s of km away and in real-time. No pigging operation is needed, no extra sensors – as the leak starts, an alert is raised with an accurate location, down to the meter. Even if there is background noise – the classification algorithms can distinguish and detect the leaks.

A comprehensive leak detection solution with AVEVA

PrismaFlow™ is offered as a part of Schneider Electric’s field-proven integrated Pipeline solutions along with AVEVA’s pipeline management solutions. Joining these two complementing solutions can give any operations manager the ease of mind, that leaks and 3rd party threats to the precious pipeline can be detected and will trigger an alarm in real-time.

Circling back to the gasoline spill in Walnut Creek, California, such a solution would have alerted way before a surprised crew of pipeline engineers appeared on site. Tiny leaks created by the strain of tree roots on the pipe cause small ruptures that fiber optic sensing can pick up and trigger an alert.

A leak detection system’s power is presented when it detects such a catastrophe and when it does not alarm any wild boar digging above the pipe.

PrismaFlow™ is now available on the Schneider Electric Exchange shop. Be sure to read more and learn how to turn on leak detection from afar. Visit shop - https://shop.exchange.se.com/en-US/apps/67746/leakage-detection-system-for-ecostruxure-ogp

Author

Link copied. Please paste this link to share this article on your social media post.

Would you like to add a comment?

All registered members have full access to the Community and can post comments and start topics.

Create your free account or log in to subscribe to the forum - and gain access to more than 10,000+ support articles along with insights from experts and peers.