Regain Control of your Consumer Product Data – Part II

Solutions for your Business Forum

No matter if your business is in the retail sector, food manufacturing, or healthcare, you'll find resources and a community of experts to discuss with on content tailored to your industry sector. Subscribe today.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-03-03 04:37 AM . Last Modified: 2022-06-23 09:34 PM

Regain Control of your Consumer Product Data – Part II

In our previous post, we highlighted the importance of efficient product content management in the current competitive environment where consumers demand more trusted, transparent access to increasing relevant, reliable information on their product choices. Now in this post, let’s see how we can provide an answer to this challenge.

What is a PIM solution?

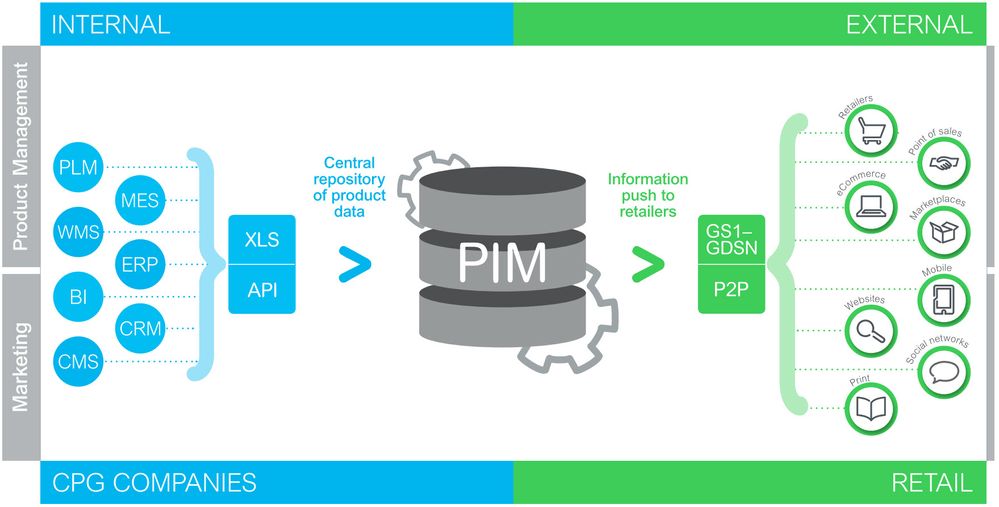

PIM stands for Product Information Management. It serves as a system of reference that centralizes all end-product data and makes it available to stakeholders internally and externally. The solution ensures data accuracy and consistency across different internal sources of information and retail channels. The data handled by PIM systems are constantly updated and should comply with GS1 standard (the common language used to identify, capture and share data between the actors of the CPG supply chain).

- A PIM solution assures that product data can be standardized, centralized, and distributed with complete security along the downstream supply chain. Therefore, it gives CPG companies a single version of truth for their product data delivering significant operational efficiencies and improved business performance.

- A PIM solution is a real productivity tool improving the marketing & the selling of CPG products through complex distribution channels, helping teams work faster and smarter throughout the product information lifecycle and making cooperation easier.

- A PIM solution should be flexible both on how the data comes into the system and how it is incrementally improved over time. And as today brands need to validate their content against requirements of retailers and the market needs (e.g. e-commerce, marketplace), PIM solutions need also to embed DAM (Digital Asset Management) functionalities and to be available in a single cloud-based platform accessible by different internal stakeholders.

Therefore, a PIM solution allows CPG companies to acquire, manage and publish product data seamlessly across all channels and synchronize product information regardless of format, language, currency or physical location.

The benefits of a PIM solution

A PIM solution may provide different types of well-known measurable benefits: strategic, tactical and operational.

Strategic benefits:

- Possibility to expand and manage efficiently the different SKUs

- Shorten time to market for product introduction: faster distribution of the information to all channels

- Uniform customer experience across all channels: 39% manufacturers confirm better level of customer loyalty with a PIM vs only 9% without a PIM

- Increased consumer experience: organizations that invested in PIM systems reported 8 to 12% greater improvement in customer retention, satisfaction and time to resolve issues over the past year vs 3 % or even declines in performance for companies not implementing this tool.

Tactical benefits:

- Management of complexity: growing number of SKUs and attributes, channels, languages, countries, suppliers, specific assortment and prices, level of hierarchy, …

- Better controlled content distribution: retailers are asking more and faster product information as a criterion to list the different products. With a PIM solution, you can provide the retailers with more and better product information earlier.

- Legal and regulatory compliance: companies with a PIM state to have 50% more better control over their data than companies without a PIM.

- A PIM solution that is GS1 compliant enables to automatically exchange information with the retailers and supply chain actors using the Global Data Synchronization Network (GDSN).

Operational benefits:

- High Quality Product Data: organizations with a PIM system reported a 17% increase in the accuracy of their product master data over the past year, more than 3 times the improvement shown by companies without a PIM.

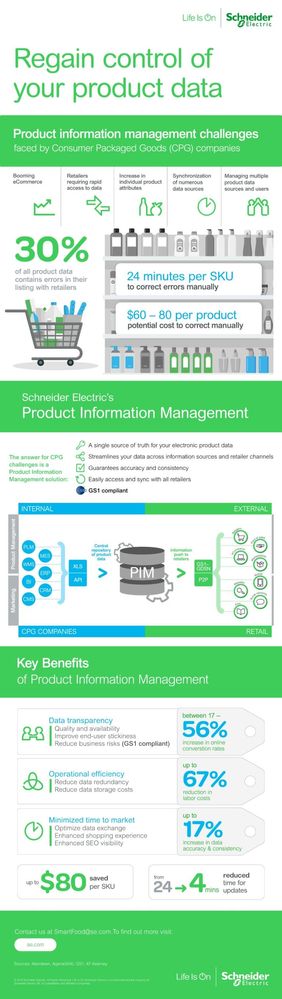

- Increased turnover: online conversion ratios can increase from 17 to 56% through better product information. Better and more accurate product information enables a more efficient keyword selection search, navigation, filter and comparison for the consumers

- Reduction of cost per product: Studies show that with a PIM solution search time to access information reduced by more than 25%. Also, a PIM solution enables faster product data editing: on average, with the introduction of PIM, time to update one product was reduced by 30%, also time to remove a product information error from the webshop was reduced by 75%. Furthermore, a PIM solution simplifies product hierarchy management offering the ability to link products to multiple hierarchies/level without duplicating data. Overall, with a PIM solution, employees need to spend less time cleaning data.

- Interfacing with other systems: avoiding the information to be updated manually. In average, 25 min per SKU is spent on manual item data cleaning each year, which would take only 4 min with an automatic synchronization. AT Kearney estimates that 30% of all article data from wholesale and producers has at least one mistake in it. It estimates the cost of correction to be between 60 and 80€ per product. With a PIM solution, you will have less rework on your product information generating concrete and measurable savings per product.

Overall operational benefits of PIM system can be significant: Aberdeen sees a 67% drop in labour cost and feedback from PIM users and shows an increase in employee productivity of 20%. Finally, in average, the payback of a PIM solution is around 6 months to less than one year.

When to consider a PIM solution

Your company has:

- To manage lots of products and product changes

- Multiple different users of product data within your company or external users

- Faces complexity generating many attributes per product and/or if your products offered differ widely

- To manage data quality and/or data compliance

- Lots of sources of product data information to synchronize across your complete supply chain

- To manage different channels (print, web, mobile, …) needing different output formats and interfaces to be supported

- To deal with different countries and languages with the need of local adaption of product content managed in an automatic mode

If you answered “yes” to these questions, then you need a PIM solution to remain competitive in your field, increase your product content management efficiency and start the digital transformation of your product data.

Regain control of your product data…

-----------------------

Originally posted on SE Blog

- Labels:

-

Food & Beverage

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-04-22 07:38 AM

Very interesting & exciting topic!!

Link copied. Please paste this link to share this article on your social media post.

Create your free account or log in to subscribe to the forum - and gain access to more than 10,000+ support articles along with insights from experts and peers.