How are Clean-in-Place Operations supporting Quality 4.0?

Solutions for your Business Forum

No matter if your business is in the retail sector, food manufacturing, or healthcare, you'll find resources and a community of experts to discuss with on content tailored to your industry sector. Subscribe today.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-03-02 08:36 AM . Last Modified: 2022-06-23 09:34 PM

How are Clean-in-Place Operations supporting Quality 4.0?

“Digital Transformation and Industry 4.0 Industry 4.0 are more than buzzwords” recently wrote by a colleague Keith Chambers. In fact, Big Data, Predictive Analytics and Industry 4.0 are all necessary to support the improvement of operational performance, as well as ensuring quality and regulatory compliance amongst other benefits.

Did you know that 23% of initiatives related to IIoT and digital transformation are focusing on quality improvement?

Few years ago, we wrote about Clean-in-Place (CIP software) operations, and the importance of optimizing them to increase your bottom line result and to ensure your operations are compliant with the latest food safety regulations & standards.

So, are you ready to go a step further and to move your CIP operations to Quality 4.0?

Why focus on Clean-in-Place operations?

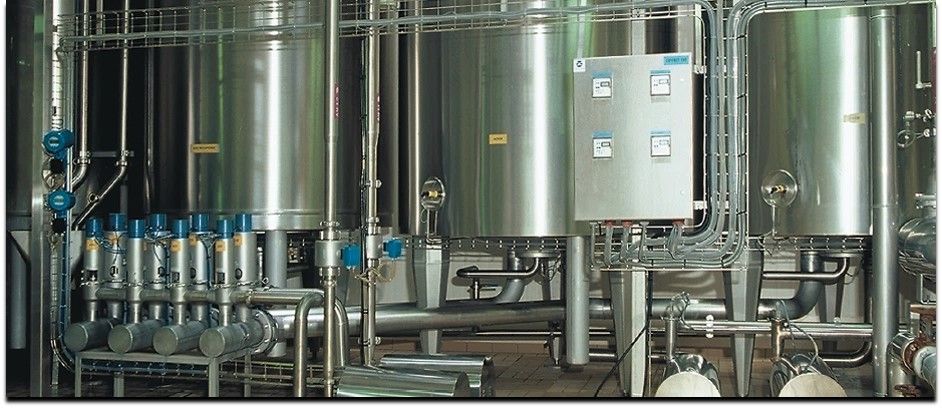

With companies managing more product variations to fulfill increasing demand from end-consumers, CIP operations become more critical. They help to ensure pipes and process equipment are cleaned before the next production cycle. But, a production manager needs these operations to be done quickly and effectively so that more time can be spent producing rather than cleaning the equipment.

Existing CIP processes are often time intensive and waste large amounts of energy, water and chemicals. However, unless they face cleanliness concerns, most F&B plant managers believe that their CIP software are working properly. Furthermore, when a CIP is delivered as a commodity system it is rarely fine tuned to the product being produced and the process specifics, making it more expensive than necessary.

There are opportunities to save time and associated costs by optimizing CIP systems. But many companies generally do not realize that the digital transformation of CIP operations can lead to further operational excellence and support Quality 4.0.

What is Quality 4.0?

Quality 4.0 is a reference to Industry 4.0. It is about the digitalization of quality management and its impact on quality technology, processes and people. As some F&B companies already started their digital journey, quality should also start its 4.0 transformation. Furthermore, in a recent study, it has been revealed that 23% of the top IoT use cases pursued by F&B companies today relate to quality improvement and monitoring.

37 % of F&B companies say poor metrics is a major roadblock to reaching quality objectives with insufficient adoption of real-time data.

But today, an impressive amount of data may be collected, from more diverse sources, in real-time, accurately and with an easier access to data sources. The F&B industry is therefore moving from traditional quality using traditional data to Quality 4.0 using big data and analytics to unlock the insights captured from a vast array of data.

Traditional quality generates descriptive metrics (what happened), diagnostic metrics (why it happened) and predictive metrics (what will happen, trend analysis) but new insights are realized with IoT such as prescriptive analytics (what action to take). So, Quality 4.0 doesn’t replace traditional quality methods but improves upon them.

Two major benefits of moving CIP operations into Quality 4.0

-

Compliance to regulation & standards

In Food and Beverage, compliance activities include conforming to regulatory, industry, customer and internal requirements. Quality 4.0 introduces more opportunities to automate compliance.

The Food Safety Modernization Act (2011) and the GFSI (Global Food Safety Initiative) series of approved schemes such as BRC, SQF, FSSC2000 and IFS set clear requirements for cleaning & disinfection of a food plant: it is not only mandatory to monitor CIP operations but also to check and document their effectiveness. Therefore, cleaning schedules, records and documents and methods for verification of cleaning and corrective actions procedures should be available.

Moving your CIP operations to Quality 4.0 allows you to better monitor and document your CIP operations providing the level of traceability required by regulation & standards.

-

Operational Excellence through Continuous Improvement

Today, major goals of F&B companies are to improve water efficiency in their manufacturing operations, by reducing water usage or minimizing water waste, and to lower the carbon emission through energy reduction.

It is estimated that CIP operations consume nearly 30% of plant utility resources. That’s why it is important that they are carried out effectively and efficiently to contribute to an overall low total cost of ownership.

Even if there are a lot of CIP data parameters available, they are generally scattered in multiple systems and hard to interpret. Furthermore, the lack of real-time monitoring of cleanliness makes it hard for operators to continuously improve their CIP systems.

With Quality 4.0, big data and analytics available in one single integrated solution, CIP operators can easily improve their Clean-in-Place systems by monitoring several key data (CIP parameters) through real-time data analysis.

Typical cost savings expected from moving CIP operations to Quality 4.0 support directly the operational excellence of F&B companies with the typical following benefits:

- 20 – 30% reduction on cleaning costs

- Higher productivity up to 15%

Conclusion

With Industry 4.0 applied to Quality, it is time to apply the digital transformation to your CIP systems.

Moving your CIP operations to Quality 4.0 enables you to:

- Ensure compliance with Food Safety regulations and collect documented evidence of applied sanitary measures while improving traceability of your CIP operations;

- Reach operational excellence through the continuous improvement of your Clean-in-Place applications and stations that will minimize your impact on the environment, boost your plant productivity by reducing cleaning time and associated costs.

Most importantly, because today Quality 4.0 is a competitive differentiator, moving your CIP operations to Quality 4.0 brings real value: improved quality, costs, efficiency, market share, and brand recognition.

Originally published on SE Blog

- Labels:

-

Food & Beverage

- Tags:

- analytics

- automation and control

- Big Data

- CIP

- clean in place

- clean in place application

- clean in place system

- cybersecurity

- Digital transformation

- food and beverage

- Food Defense

- industry 4.0

- infographic

- Innovation At Every Level

- quality 4.0

- quality management system

- Regulation Compliance

- software CIP

- traceability

Link copied. Please paste this link to share this article on your social media post.

Create your free account or log in to subscribe to the forum - and gain access to more than 10,000+ support articles along with insights from experts and peers.