How to create more efficient Plant Operations and reduce Cost?

Industry 4.0 Blog

This blog is addressing the Industry 4.0 and includes news and information aroud topics as smart manufacturing, artificial intelligence and Industrial Internet of Things (IIoT).

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Email to a Friend

- Printer Friendly Page

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

How to create more efficient Plant Operations and reduce Cost?

Originally published on Industry 4.0 Blog by cs_limaye_super | July 16, 2020 02:58 PM

Throughout most industrial operations, electric motors play a critical role in driving conveyor belts, pumps, compressors, agitators, fans, and other critical infrastructure assets. As the number of motors in process plants increases, management and monitoring of such assets is critical in preventing core process errors such as the proper mixing of ingredients. Motors also account for about 70 percent of the total energy consumed in a process plant. A strategy that links motor control, automation, and energy management, therefore, can help plants to simultaneously reduce costs while increasing production.

Motor failure can be expensive as it can cause plant stoppages, damage to equipment, and risk to people or the environment. Robust connection and communication between the motor and the automation system plays an important role in minimizing instances of motor failure. In addition, overall energy costs are reduced when energy data from motors is monitored so that function can be better aligned to workload.

Most companies fail to pursue the strategy of Integrating motor control, automation, and energy systems because of the perceived technical complexities. However, seasoned systems integrators with knowledge in all three of these domains can help plant operators to combine and optimize these systems, thereby helping to drive profitable production.

How to Improve Motor Operation and Uptime

Improved motor operation and uptime can be achieved through several approaches that can be used in tandem with the automation system for performance optimization. Here are some components that can play a role in improving motor reliability, efficiency, and uptime:

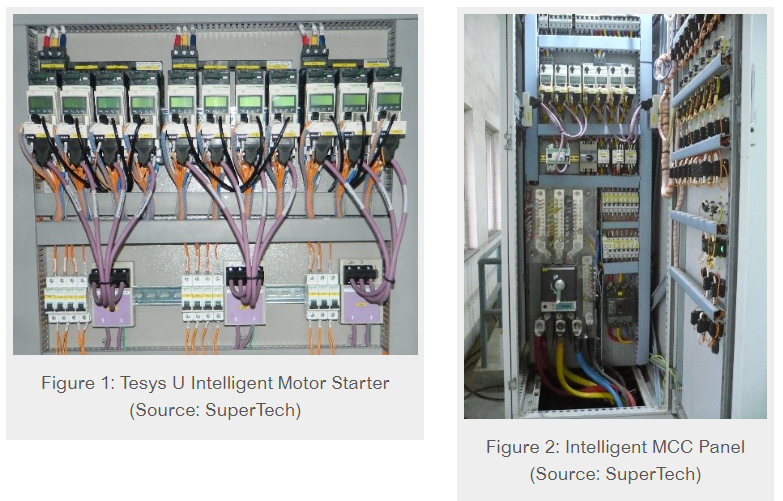

- Intelligent motor controllers and relays – Relays are electro-mechanical devices that can provide basic functions such as turning the motor on and off. Intelligent motor controllers can provide an automatic means for motor starts and stops, forward or reverse rotation, regulation of speed, limitation of torque, and protection against overloads and electrical faults.

- Variable Frequency Drives (VFDs) and soft-starters – These devices fall into the category of intelligent motor starters. Since motors can provide a rich array of performance data, VFDs can interpret this data and aid in failure prevention, in predictive maintenance, and in energy management.

- Motor control centers (MCCs) – MCCs allows plant operators to control some or all electric motors from one central location. Such an approach increases reliability, reduces wiring costs, and lowers the risk of human error. In a plant with 100 motors, for example, more than 500 PLC-related I/O with associated wiring will be required. This wiring can be eliminated by connecting an Intelligent MCC to an automation system via a communication bus. The bus itself enables the communication of warnings, alarms, and motor parameters to the automation system.

Tips for Optimizing Motor Control Performance

When we at Supertech, an automation systems integrator and certified Schneider Electric Alliance Partner for Control System, Hybrid DCS, Intelligent MCC, and EcoXpert, engage in industrial automation systems and energy solution integration projects, we are often asked to advise the best approach for designing and implementing motor control solutions. Listed below are some important hints and tips for deriving the full benefit from MCC-related investments:

Ensure intelligent MCCs are configured for proper communication

An intelligent MCC is much more than just a metal box with electronics inside. In the digital solution era, where data plays a critical role in optimizing operations, the value of the intelligent devices inside the panel is what really counts. The components are intelligent and hence require configuration. Many panel builders do not possess these skills and they often produce panels that can run the motors in local mode but cannot communicate with automation systems. Such a situation (inadequate communications configuration) can cause costly delays during plant commissioning. Users should ensure that the systems integrator who designs and configures the MCC has the expertise, track record, and certification from the manufacturer to perform the necessary work.

Choose the bus component that best meets your factory floor need

Three levels of buses are available for communication back to the automation system–Modbus (RS-485), Profibus or Canopen, and Ethernet.

- Modbus is less expensive but is not recommended for motor control applications because of its slow speed. It is acceptable for monitoring but not for both monitoring and control.

- Profibus or Canopen can work, but be aware, the speed of these networks reduces when the number of devices connected and the length of the bus increases. They are also prone to electromagnetic noise disturbances unless precautions are taken while laying out communication cables and grounding.

- Ethernet is slightly more expensive but performs the best in terms of speed, data transfer capacity, flexibility, reliability, ease of installation, and resistance to noise. Ethernet devices also have built-in web servers and configuration tools that makes installation, commissioning, and diagnostics easy.

Seize the Opportunity to Integrate Automation and Energy Management

Intelligent motor control provides energy consumption data for each motor. Multifunction meters and intelligent breakers are used for monitoring the quality and quantity of electrical energy. Data from all these devices can be captured by energy monitoring systems such as Schneider Electric’s Power Monitoring Expert (PME) and Power SCADA Operations (PSO). These systems output management information reports and dash boards, which help to significantly reduce energy costs.

For More Information Motor Control and Automation Solutions

To learn more about how these solutions can combine with both energy monitoring and motor control solutions, read our blogs:

- “Why New Generation Automation Solutions Excel in Hybrid Process Environments”

- “3 Ways Choosing the Right Hybrid Industry Automation Integration Partner Can Minimize Project Risk”

-----------------------

Originally posted on SE Blog

About the contributor:

Tanaji Bhosale, Sr. Manager – Projects, brings 25+ years of experience and in-depth knowledge of Electrical Design & Detailed Engineering. He is an expert in project management and advanced Intelligent Motor Control Centers / Smart Panels and has expertise in Electrical Distribution Energy Monitoring & Controlling.

As a project manager, Tanaji is involved in everything from proposal discussion and planning to procurement and from FAT and SAT executions to after-sales support. His list of satisfied clients includes: IDMC Ltd, Watson Pharma Ltd, Lubrizol Ltd, Kansai Nerolac Paints Ltd, K.V Arochem, V.N. Creative Ltd, and CEAT Ltd.

- Tags:

- alliance partners automation

- energy automation

- english

- hybrid processes

- Industrial Automation

- intelligent motor controls

- motor control

- plant

- scada

- Schneider Electric Exchange

- supertech

Author

Link copied. Please paste this link to share this article on your social media post.

Would you like to add a comment?

All registered members have full access to the Community and can post comments and start topics.

Create your free account or log in to subscribe to the forum - and gain access to more than 10,000+ support articles along with insights from experts and peers.